Sand Blasting & Painting service

Reach us for Sand Blasting and Painting, Protective Coating works anywhere in the UAE – Abu Dhabi, Dubai, Sharjah, Fujairah, Ras Al Khaima, Ajman & Umm Al Quwain.

Our qualified team in abrasive blasting and protective coating application and will ensure your structure or equipment are free from grease, rust and surface contaminants with precise attention to detail. We offer on-site and off-site abrasive blasting, and our equipment allows us to clean and prepare nearly any material in any texture you desire.

We Provide Following Sandblasting & Painting Services:

- Steel Pipes & Tubes

- Storage Tanks & Silos

- Pressure Vessels

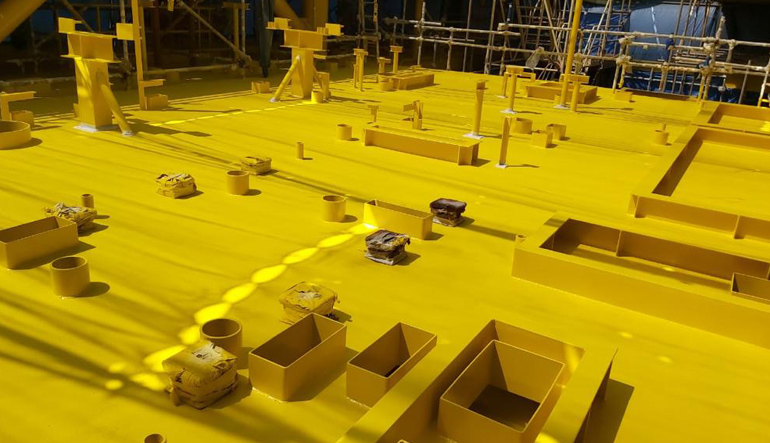

- Ship Decks & Bulkheads

- Steel Structures

- Oil & Gas Facilities

Enhancing Durability and Performance Through Blasting and Painting

At Petroline Technical Services, we recognize that the proper preparation of surfaces as well as protective coatings is essential for the long-term stability for your assets in the industrial sector. Our blasting and painting services are specifically designed to ensure that your structures are not corrosive and durable to wear and able to endure extreme environmental conditions for years to the future.

Each project is unique and therefore requires its own specific approach in order to ensure that your equipment and surfaces are treated with the utmost quality. Whether its extreme industrial sandblasting, or a light touch surface prep on a marine vessel, we can accomplish that with accuracy.

Key Benefits of Our Blasting and Painting Services

Superior Corrosion Protection

Our sandblasting will take off all rust, old coatings, and other contamination leaving a clean smooth surface for good paint adhesion. The coatings that we apply serve as a barrier against corrosion, which in turn will prolong the life of your assets.

Customized blasting and painting for Every Project

No two projects are the same. We customize our blast and paint processes around the material, application, and atmospheric conditions that your equipment or structures will be subjected to. From steel pipes to pressure vessels, we deliver tailored solutions that meet your unique requirements.

Versatile Applications

Our blasting and painting services cater to many industries, such as oil gas, marine, and construction. From the preservation of steel structures to the upkeep of ship decks, our trained staff has the answers.

Enhanced Aesthetic and Structural Integrity

Our painting services do more than just provide anti corrosion properties, it makes your assets look good, an overall better appearance, a nice clean professional looking finish. It is not just the coatings that give this advantage, but they also provide an additional barrier of protection from abrasions, chemical contact, and wear from the environment.

Environmentally Friendly Approach

We utilize eco-friendly blasting materials and coating solutions to minimize environmental impact while maintaining high safety standards. Our procedures ensure that your project complies with local environmental regulations.

Our blasting and painting Process: Precision from Start to Finish

- Assessment and Planning: Every inspection starts with a close look at your equipment/structure. We have the correct media for blasting and the most effective coating for it.

- Abrasive Blasting Method: Our team uses sophisticated abrasive blasting techniques that eliminate paint, rust and other contaminants. We blast using different materials, such as sand glass beads, and steel shots, based on the materials and the finishing.

- Protective Coating Application: And then, when the surface is prepared, we apply some industrial strength protective coatings. And not even used for anti corrosion purposes, but for strength and beauty too. We do all kinds of coatings from epoxy, to polyurethane, to specialized protective products.

- Quality Control: We do, however, perform full quality inspections all the way down the line to ensure that our blasting and painting meets our standards of high quality and safety.

Industries We Serve for Sand Blasting and Painting

Our blasting and painting services extend to numerous types of industries such as:.

- Oil & Gas: We do surface prep and coating for oil gas facilities for corrosion and erosion protection in very corrosive atmospheres.

- Marine: We blast and paint ship decks, bulkheads, and any other marine structure to insure that it will last as long as possible against the salt water.

- Construction: Keep your steel, pipes, and concrete safe with our trained services made especially for the construction field.

- Industrial Facilities: From storage tanks to pressure vessels, our services ensure your industrial facilities remain operational and corrosion-free.

Blasting and painting services all over UAE

Protect your investments now with Petroline Technical Services professional sand blasting and painting. Be it Abu Dhabi, Dubai, Sharjah, Fujairah, anywhere in UAE, wherever you are we will give you the best surface preparation and coating services.

Contact us

Contact us right now for a free consultation or estimate +971 3 722 00 95, or websales@petrolinetech.com. We can help you prolong the life of your machine by customized sand blasting and painting.

Frequently Asked Questions (FAQs)

1. Blasting, painting are really important?

Blasting and painting is the technique of preparing the surface for painting by blasting any contaminants like rust and grease prior to applying a protection coating. Each step is vital to stop corrosion, increase the lifespan and also improve the visual and structural integrity of industrial components.

2. What materials can you work with?

We work with a variety of materials including steel, concrete, and metal surfaces. Our blasting and coating techniques are tailored to suit the specific needs of each material and industry.

3. How long does the blasting and painting process take?

That would be time consuming, but it’s not the same when it comes to work load and the scale of the project. It could be a couple of days with smaller objects, but larger structures or more intricate surfaces can take much much longer. We will complete your project in time without compromising work quality.

4. What coatings do you use?

We provide a selection of top-quality coatings like polyurethane, epoxy, and other specialized protective coatings. Each coating is chosen depending on the environmental aspects and performance requirements that the building needs.

5. How frequently is my equipment supposed to be blast and paint?

However, that depends on what field your machinery is in. For example, in the case of equipment in severely corrosive environments, it is recommended that the equipment be checked and the protective coating be upheld at intervals of 1-2 years.